Methane (CH₄) is one of the most widely used gases in industrial, commercial, and residential applications. It serves as a primary component of natural gas, fuels countless heating systems, and plays a central role in energy production and chemical processes. Despite its usefulness, methane is also highly flammable and contributes significantly to greenhouse gas emissions when released into the atmosphere. To manage these risks, industries rely on advanced gas detection technologies such as the methane sensor and high-precision tools like the ndir gas sensor. These sensors are essential for ensuring safety, improving efficiency, and detecting leaks before they lead to dangerous or costly situations.

Understanding how methane sensors work—and why they are so crucial—helps clarify their growing importance across modern infrastructure, from energy facilities to smart-home systems.

1. The Importance of Methane Monitoring

Methane is odorless in its natural form, making leaks difficult to detect without specialized equipment. Although utility companies add odorants like mercaptan for residential use, many industrial environments work with pure methane or methane blends that offer no sensory warning of leaks.

Unmonitored methane can lead to:

- Explosion hazards — Methane becomes explosive at concentrations of 5–15% in air.

- Suffocation risks — High methane levels can displace oxygen in confined spaces.

- Environmental damage — Methane is over 25 times more potent as a greenhouse gas than CO₂ over a 100-year period.

- Operational losses — Undetected leaks waste energy and increase costs.

Methane sensors play a vital role in identifying leaks early, ensuring systems operate safely and efficiently.

2. How Methane Gas Sensors Work

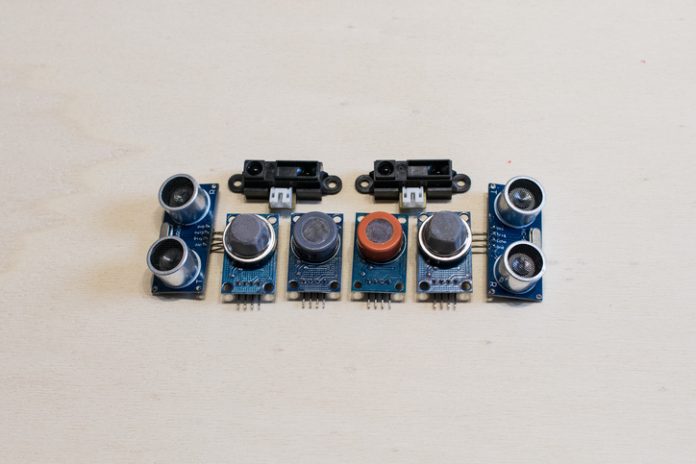

Methane detection technologies use various sensing principles, each suited to specific environments and performance requirements. Below are the most commonly used types.

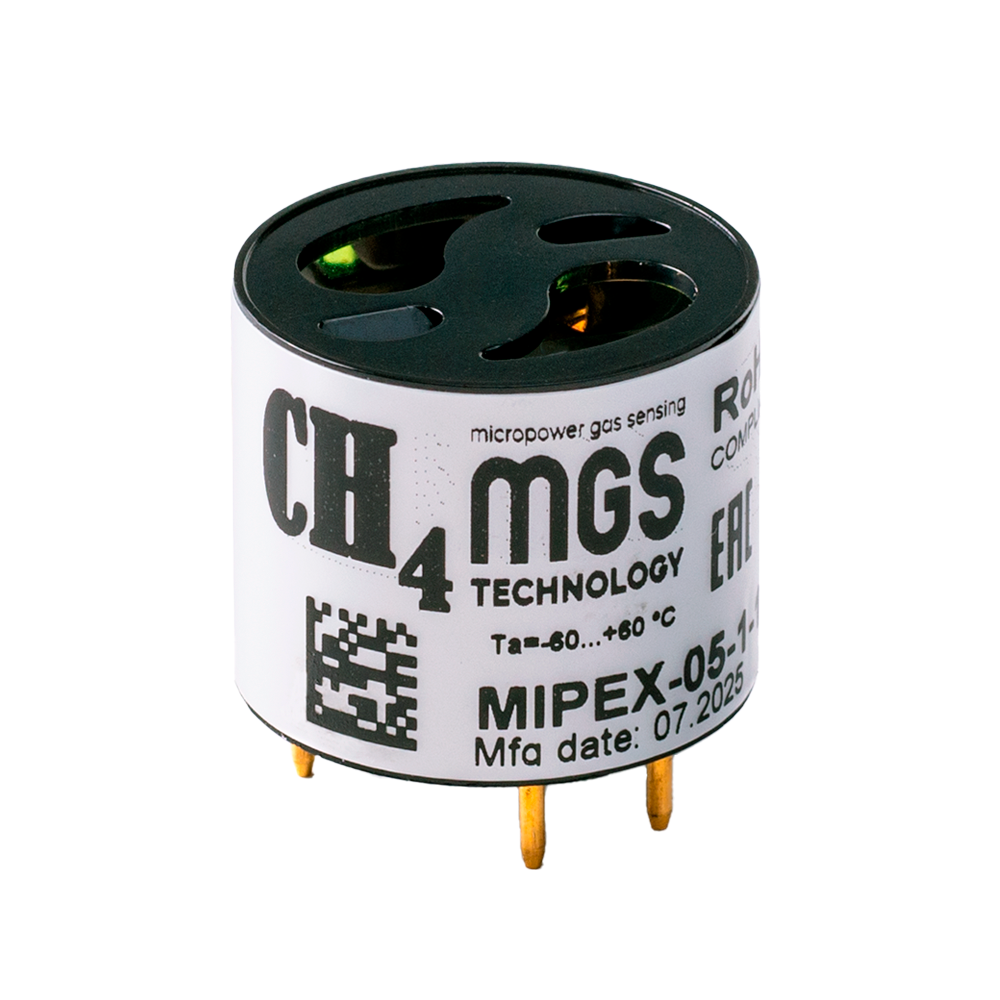

A. NDIR (Non-Dispersive Infrared) Methane Sensors

NDIR sensors are widely considered the gold standard for methane monitoring due to their reliability, accuracy, and immunity to cross-interference.

How NDIR sensing works:

- Methane absorbs infrared light at characteristic wavelengths.

- An IR source emits light through a chamber containing the sampled air.

- A detector on the opposite side measures how much light was absorbed.

- The amount of absorbed light corresponds to the methane concentration.

Benefits of NDIR methane measurement include:

- High accuracy and stability

- Long lifespan

- Resistance to humidity and contamination

- Very low false-alarm rates

Because of these advantages, many advanced methane detection systems incorporate an ndir gas sensor for precise monitoring.

B. Catalytic (Pellistor) Sensors

Catalytic bead sensors detect methane by measuring the heat produced when the gas burns on an active catalytic surface.

How they work:

- The sensor heats a catalyst bead to a high temperature.

- Methane oxidizes on the bead’s surface, releasing heat.

- The temperature shift changes the bead’s electrical resistance.

- The system interprets this change as methane concentration.

These sensors are effective and cost-efficient but require oxygen to operate and may drift over time.

C. Semiconductor Sensors

Semiconductor methane sensors detect gas through a change in electrical conductivity on a metal oxide surface.

Key characteristics:

- Simple design and low cost

- Good sensitivity to methane

- More susceptible to humidity effects

- Ideal for consumer and residential applications

D. Laser-Based Methane Sensors

Laser absorption spectroscopy uses highly specific wavelength targeting to detect methane light absorption.

Advantages:

- Extremely fast response

- Very high selectivity

- Capable of long-distance leak detection (even aerial monitoring)

Although these sensors are more expensive, they excel in pipeline, industrial, and environmental monitoring.

3. Where Methane Sensors Matter Most

Methane detection is essential across multiple industries, ensuring safety, regulatory compliance, and operational continuity.

A. Oil and Gas Sector

From extraction to transportation, methane is present throughout the energy supply chain. Sensors are used to:

- Prevent explosions at drilling sites

- Detect leaks in pipelines and storage tanks

- Monitor emissions to meet environmental regulations

Even small leaks can cause catastrophic failures, making detection systems indispensable.

B. Industrial Manufacturing

Industries using methane for combustion, chemical processing, or heating rely on sensors to maintain safe working environments.

Applications include:

- Boilers and furnaces

- Power generation turbines

- Chemical reactors

Continuous monitoring ensures both worker safety and optimal system performance.

C. Residential and Commercial Buildings

Natural gas appliances—including stoves, heaters, and boilers—can leak methane if damaged or improperly maintained. Sensors help:

- Protect occupants from fire risks

- Automatically shut off gas supply during dangerous leaks

- Integrate with smart-home alert systems

With the rise of smart building technologies, methane detectors are becoming as essential as smoke and carbon monoxide alarms.

D. Environmental Monitoring

Methane emissions contribute significantly to climate change. Advanced sensing systems are used to:

- Track emissions from landfills

- Monitor agricultural sources (e.g., livestock)

- Analyze atmospheric methane concentration trends

High-accuracy sensors, including NDIR and laser-based models, are key to identifying and reducing methane sources.

4. Why Methane Sensors Are More Important Than Ever

Several global trends are increasing the need for methane detection:

A. Expanding Natural Gas Infrastructure

As natural gas remains a dominant global energy source, more infrastructure means more potential leak points.

B. Stricter Environmental Regulations

Governments now require methane emission reporting and reduction strategies.

C. Growth of Smart and Automated Facilities

Modern buildings require integrated safety systems that continuously monitor gas levels.

D. Advances in Sensor Technology

Improved NDIR and IoT-enabled sensors allow for remote monitoring, predictive maintenance, and automated shutdown protocols.

Together, these factors make methane sensors a foundational component of modern safety and environmental management systems.

Conclusion

Methane sensors are critical tools for protecting people, property, and the environment. Whether using catalytic, semiconductor, laser, or advanced NDIR technologies, these sensors provide the early warning systems necessary to detect leaks, prevent disasters, and reduce emissions. High-performance solutions such as the methane sensor and precision ndir gas sensor deliver the accuracy, reliability, and responsiveness required across industrial, commercial, and environmental applications.

As global reliance on methane continues, and as efforts to control emissions grow more urgent, methane detection systems will remain a cornerstone of safe and sustainable operations.

Disclaimer: This article contains sponsored marketing content. It is intended for promotional purposes and should not be considered as an endorsement or recommendation by our website. Readers are encouraged to conduct their own research and exercise their own judgment before making any decisions based on the information provided in this article.