The human eye was the original inspection tool. Its limit was geography. One person, one place, one time. For a century, the steel ribbon was blind. It knew only weight, vibration, and the slow creep of decay. Its secrets, the hairline fracture, the loose fastener, the subtle warp, were kept until a human eye, by chance or by schedule, found them.

The rail video data platform is a new kind of vehicle. It does not transport a person. It transports their expert gaze. It lets a single engineer ride a thousand trains at once, to stand on a thousand miles of track from a single chair.

Here are the nerve centers that make this superpower a reality.

Boots Off, Data On: Why You Need This Technology

Here is why you need a rail video data platform.

- It grants your team trackside presence, without the trackside risk. Safety and efficiency begin at the desk.

- The system shifts your posture from reactive repair to proactive control. It sees the problem before it stops a train.

- You gain a perfect visual memory of your network. Travel back in time to review a site’s condition from previous seasons or years.

- This visual record becomes the ultimate source of truth, the foundation for all future maintenance and upgrade plans.

The Mark of a Great Platform

Here is what you should look for in a rail video data platform.

- Look for true intelligence, not just a video library. The AI should find the faults for you, specific to your network.

- The platform must connect. It should integrate with asset lists and track geometry data, so information can flow.

- Demand absolute clarity. You need to see the hairline fracture, not a blurry approximation.

- Prefer a solution from a single house. One vendor for hardware, software, and support means total accountability.

- The best tool is simple. It should require only a web browser and a login for full access to its power.

Best Rail Video Data Platforms

If you are looking for reliable rail infrastructure inspection tools, here are some of the best options.

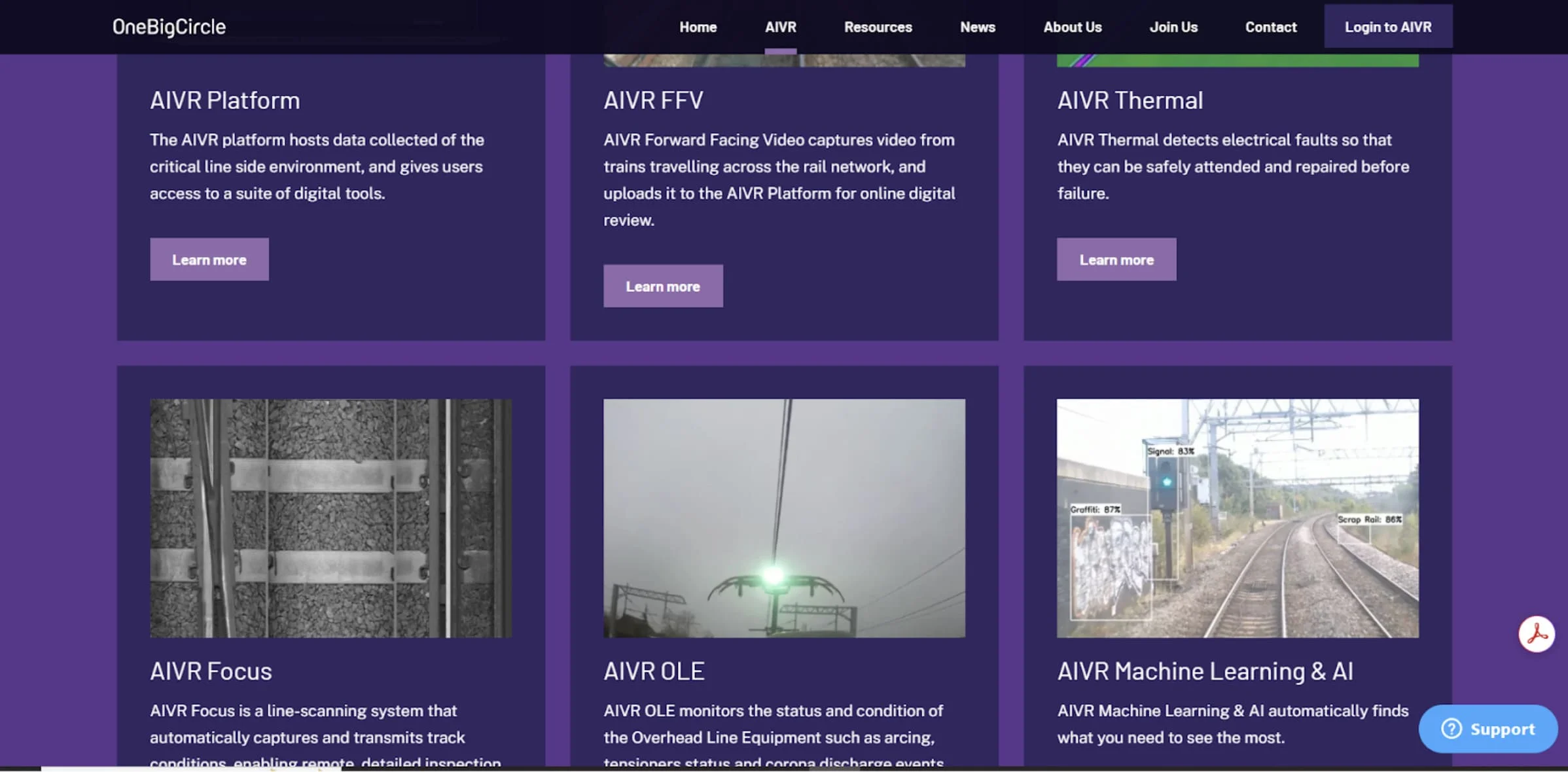

One Big Circle’s AIVR

One Big Circle’s AIVR is the platform that transforms physical track into actionable digital vision, delivering real-time insights from rail video data directly to your browser.

Key Features:

- Log In to Your Railway: No installs, no special software. AIVR places the power of your entire rail network inside any modern web browser, ready when you are.

- A Half-Million Mile Visual Record: This vast video archive, one of the world’s largest, serves as the foundation for a true digital twin of your infrastructure.

- The System That Sees Faults First: Bespoke AI acts as a tireless digital inspector. It automatically pinpoints hotspots, railhead contamination, and asset defects for predictive repairs.

- Crafted Under One Roof: From camera hardware to platform code, the entire AIVR ecosystem is a product of One Big Circle’s own team. The result is a seamless, purpose-built tool.

- Boots Off The Ballast: Conduct site surveys, plan safe work zones, and perform virtual signal sighting. AIVR removes the need for countless physical trips to the trackside, a step-change for safety and operational speed.

- Intelligent Thermal Monitoring: High-resolution infrared video and advanced Machine Learning automatically identify high-temperature ‘hotspots,’ providing early warnings of potential faults and shifting maintenance from reactive to truly predictive.

Rail Vision

This is an intelligent lookout for your locomotive, designed to give the train driver a clear, real-time view of the track ahead.

Note: Unlike other platforms on this list focused on infrastructure analysis, Rail Vision is an onboard, real-time obstacle detection and driver-assistance system.

Key Features:

- A Two-Kilometer Head Start: Onboard sensors grant the operator a clear visual of the track up to two kilometers away, a power that eliminates surprises.

- The Unmistakable Warning: The system provides both sight and sound alerts inside the cab. A clear, immediate signal when a hazard appears on the line.

- Instant Obstacle ID: The AI does not just see an object; it identifies it. A person, a vehicle, a fallen tree — the system knows the difference and informs the crew.

- Eyes on the Track: Designed for zero-effort operation. The interface is hands-free and intuitive, so the driver’s focus remains on the journey, not the technology.

Trimble Track Surveying

Trimble Track Surveying is the surveyor’s toolkit for the digital age, mapping every inch of rail with absolute precision.

Key Features:

- From Dirt to Data: A complete solution for every stage of track work, from initial earthwork surveys to final quality control.

- The As-Built Authority: Capture the precise, real-world state of your track and clearance zones, creating a perfect digital record.

- Tamping, Perfected: Conduct pre-measurement surveys that feed directly into tamping machines for exact track geometry correction.

- Bridging Worlds: This is Trimble’s core strength, a seamless connection between the physical track and its digital twin, from tunnel scans to aerial surveys.

Fugro’s RILA

Think of this as the high-tech passenger that surveys the railway, creating a precise digital “Track Twin” from the comfort of a scheduled train.

Key Features:

- Survey at Linespeed: The RILA system hitches a ride on in-service passenger or freight trains, gathering engineering-grade data without the need for special timetables or track closures.

- The “Track Twin” Delivered: A dynamic 3D model of the entire rail corridor, built from lidar, video, and track scanners. It’s a complete digital replica, accessible from a web browser.

- Data for Every Department: Born from the principle of “survey once, use many times,” the captured data serves countless needs, from clearance gauging and asset management to electrification design and vegetation analysis.

- A Safer, Deeper Look: This method removes survey teams from the trackside. Its continuous scan captures a level of detail impossible with traditional stop-and-start manual surveys.

From Spotting Damage to Understanding Risk

Right now, this technology is like giving a track inspector an incredible pair of binoculars. It lets them see more, faster. The next step is to give them a crystal ball. We’re moving away from just finding existing damage and moving toward calculating the risk of future failure. Soon, the system won’t just flag a worn section of rail; it will tell you, “Based on this train tonnage, this weather, and the performance of 5,000 similar sections, this exact spot has a 70% chance of needing replacement in the next eight months.” This turns the engineer’s job from a search-and-find mission into one of strategic management, letting them use their budget and crews with an almost unfair advantage against wear and tear.

Summing Up

The track now speaks. It uses a language of light pulses and pixel-perfect detail to report its own health. A loose bolt is a sharp cry; a patch of worn rail is a low murmur.

The platforms in this list are your interpreters. They make sense of the noise. Your choice is not about software; it is about who you trust to translate the vital signs of your network. The right choice means you never miss a word. The conversation between steel and surveyor has begun, and it promises a future with no unwelcome surprises.

Disclaimer: This article contains sponsored marketing content. It is intended for promotional purposes and should not be considered as an endorsement or recommendation by our website. Readers are encouraged to conduct their own research and exercise their own judgment before making any decisions based on the information provided in this article.