It seems wherever you read, people are either fascinated with automation or downright scared of it. For companies, it presents endless possibilities for innovation and cost reduction. For the general population, it can bring visions of either flying cars or the world being taken over by robots.

Fortunately, present-day automation isn’t that scary. It’s mostly designed to make things easier, safer and more efficient for humans.

Collaborative robots

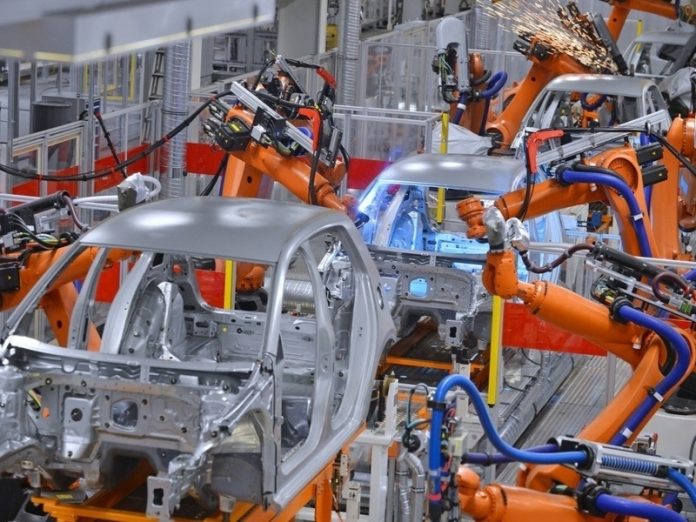

In the manufacturing industry, automation is quite a divisive issue. It can mean a significant loss of jobs in the manufacturing sector. However, automation doesn’t have to replace manufacturing jobs, it can be used alongside workers to improve their efficiency. In industries, these pieces of automation are referred to as collaborative robots or ‘cobots’ for short. Companies like Universal Robots and Robotiq are leading the way to more streamlined manufacturing systems.

These “cobots” are designed to make workers’ lives easier by reducing monotonous, repetitive tasks and reducing workplace injuries. They are widely employed in various industries, from manufacturing to even medicine.

In a lot of medical clinics, for example, doctors use the Da Vinci Surgical System to perform surgery. Doctors provide detailed instructions to the system, and the robot arm carries out precise, delicate surgical tasks. This reduces the chance of human error and saves stress for the doctor.

How Automation Can Be An Asset

The biggest potential for robots however right now is reducing workplace injuries, especially in the manufacturing sector. This sector consists of manufacturing assembly lines, material handling and transport. In other words, the industry where workers are spending long hours carrying out monotonous tasks and dealing with sharp and heavy objects.

Looking at workplace injury statistics, there is a strong case for automation. In the year 2017 alone, companies lost 104 million working days due to workplace injuries or accidents.

Injuries don’t come cheap either. US companies spend $95 million per year on employee compensation. Breaking these numbers further down reveals that on average the cost of each workplace injury was $39,000.

These statistics are especially important for manufacturing. In a report released by the Association of Workers Compensation Boards of Canada, manufacturing had the 2nd highest fatality rate for workplace injuries, with 160 fatalities.

Where do these injuries come from? Musculoskeletal injuries resulting from repetitive physical exertion (RSI) are the key contributor. According to Ergonomic Trends, almost 2 million Americans are inflicted by RSI each year, with 600,000 requiring time off from work to recover.

Back injuries in particular, are commonplace in all sectors, accounting for 38.5% of all musculoskeletal injuries. These are the result of workers sitting in one place incorrectly for hours on end and having to lift heavy objects constantly (in warehouses for example).

How robots improve manufacturing jobs

There are four main goals of automation in the manufacturing, material handling and transport sectors:

- Reduce worker fatigue- Worker fatigue increases the likelihood of errors and accidents.

- Reduce human error- Robots can carry out small, intricate tasks more consistently and accurately.

- Improve efficiency- Robots can carry out repetitive tasks for long hours.

- Help lift heavy objects

- Prevent workers falling from high levels- Automated systems can reach higher levels in warehouses that are too high for human workers.

Robots developed by NASA and Carnegie Mellon University for example are used extensively in shipping facilities to transport carts filled with items. A human worker simply has to unload the items onto a truck when it’s time to transport them away. The robots have a triple-check safety feature to reduce incidents, where the robot automatically senses other objects and people near it to prevent a collision.

At BTC Mold, a Taiwanese injection moulding company, Universal Robots supplied robots to minimize workplace injuries. Before their introduction, workers had to bend down to lift boxes of shoe horns. Doing this repeatedly is not healthy for the spine, shoulder and knee joints, increasing risk of musculoskeletal injuries. robots have now replaced this task. Not only does this reduce injury risk, but also frees up workers’ time and improves productivity.

At Ralawise, an apparel distribution firm, the company wanted to reduce the risk of cutting injuries and the use of cutting tools in general by workers. So, it teamed up with Toshiba Machine Robotics to implement an automatic custom box cutting solution. The robot can work on boxes of all sizes, by automatically sensing dimensions and edges, and choosing the cutting lines accordingly.

Machinery Automation Solutions

As mentioned, manufacturing companies can streamline and simplify their production using machinery automation. For processes that are too delicate or risky for workers to handle, many manufacturers have come to rely on production automation machinery.

Examples include robotic assemblers, cartoning and case packer machines, sorters, lidders, palletizing and conveyor solutions, and robotic automation systems.

Cartoning machines can help increase a manufacturing company’s operational productivity and compliance with industry standards. For instance, cream cheese and other dairy products require packing precision in a hygienic environment. Manufacturing companies can achieve this goal by embracing automation, consequently reducing material waste and ensuring compliance with safe food handling regulations.

Case packer solutions provide automatic case packing that can significantly improve production output. Manufacturers may work with a reputable automation machinery provider to build case packer machines that take into account their unique product design, conveying needs, factory footprint, unit throughput, hygiene requirements, and budget.

On the other hand, palletizing solutions maximize the product amount per load. This machine automation solution ensures product stability and quality, especially for products with complex shapes and sizes. Indeed, automated palletizing streamlines the production line and drives efficiency in manufacturing companies.

Robotic automation systems spare workers from repetitive manual tasks. By employing these innovative solutions, manufacturers can deliver reliable, accurate, and quality products to their customers. This technology is trending across different industries, especially in the manufacturing industry.

Takeaway

In a world where automation seems to be replacing humans, robots are designed to work with humans instead of replacing them. They reduce the risk of injury by taking over monotonous, repetitive tasks and hence reducing worker fatigue. They can also carry out more dangerous tasks like lifting and transporting heavy objects in manufacturing facilities.