Introduction

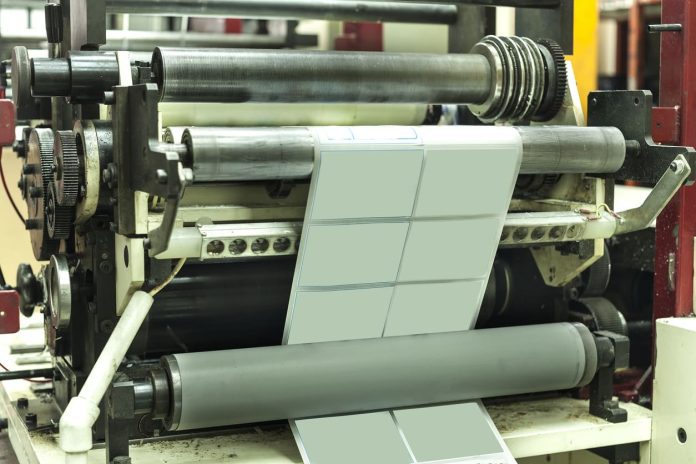

In the ever-evolving realm of fashion and apparel printing, Direct-to-Film (DTF) printing stands out for its versatility and high-quality results. As businesses and individuals strive to make a distinctive mark in the industry, the demand for durable, long-lasting prints becomes paramount. This comprehensive guide delves into expert strategies to ensure your DTF prints not only capture attention but also stand the test of time.

1. Starting with High-Quality Equipment

The journey to durable DTF prints begins with the right equipment. A prime example is the A4 DTF printer, a powerhouse designed to handle PET films at the A4 paper size, perfectly accommodating standard shirt sizes. These printers, like those offered by Procolored, are tailored for DTF printing, ensuring each print is precise and consistent. This is crucial, as the equipment’s quality directly influences the longevity and vibrancy of the prints.

2. Selecting Optimal Films and Inks

The choice of film and inks is pivotal in DTF printing. High-grade PET films ensure clean, complete transfer of designs onto fabrics, while premium DTF inks contribute to the creation of vivid, fade-resistant images. These inks are formulated to solidify effectively with the transparent adhesive, forging a bond that resists washing and wear, thereby enhancing the print’s durability.

3. The Importance of Proper Curing

Proper curing of the ink on the PET film is a critical step. This process solidifies the ink, preparing it for transfer. Adhering to the manufacturer’s recommended curing times and temperatures is vital. Under-curing can lead to poor adhesion and reduced durability, while over-curing might make the ink brittle and prone to cracking.

4. Mastering the Heat Pressing Technique

The heat press is where the design transitions from film to fabric. Optimizing the heat press settings—temperature, pressure, and time—is essential for different fabric types and ink sets. Consistent medium to high pressure ensures complete contact of the design with the fabric, while appropriate temperature and time settings activate and secure the adhesive’s bond.

5. Understanding Fabric Compatibility

Understanding the specific characteristics of different fabrics is crucial in the world of DTF printing. Natural fibers like cotton are typically more receptive to DTF transfers, absorbing the ink more effectively and providing a strong bond. However, when working with synthetic fibers such as polyester or blends, the approach needs to be more nuanced. These materials often require lower heat settings or adjusted pressing times to prevent damage to the fabric and ensure proper adhesion of the print.

Experimentation and testing are key. Prior to embarking on large-scale production, it’s advisable to conduct trials with the selected fabric. This not only helps in fine-tuning the heat press settings but also in assessing the overall look and feel of the print on different materials. Understanding fabric behavior under heat and pressure can significantly improve the end result, ensuring that the prints not only look exceptional but also last longer.

6. Post-Press Garment Care

After the transfer process, the way the garment is treated can greatly affect the longevity of the print. Immediate care is important: the garment should be laid flat and allowed to cool down. This prevents the adhesive from shifting or cracking, which can happen if the fabric is stretched or folded while still hot.

Educating customers on how to care for their printed garments is also vital. This includes washing instructions such as turning the garment inside out before washing, using cold water, and avoiding harsh detergents. Tumble drying should be avoided or done at low temperatures. When ironing, it’s crucial to avoid ironing directly over the print. Providing these instructions as part of the product packaging or as a care label can help ensure that the customers are aware of how to best maintain the print quality.

7. Implementing a Robust Quality Control Process

Quality control is a critical step in the production process. Implementing a systematic approach for inspecting the prints can prevent potential customer dissatisfaction and returns. This process should check for clarity, color accuracy, adhesion, and any signs of cracking or peeling. It’s also important to inspect the edges of the print, where lifting might occur.

Regular calibration and maintenance of equipment play a significant role in maintaining quality. Keeping the printers and heat presses in optimal condition ensures consistent quality output. Training staff to identify and rectify common printing issues can also help maintain high standards. A quality control checklist can be a useful tool, providing a standard for employees to follow and ensuring every product meets the set expectations.

8. Spotlight on Procolored’s A4 DTF Printer

Procolored’s A4 DTF printer stands as a benchmark in the field of DTF printing, exemplifying how advanced technology can streamline the printing process while enhancing quality. One of the key features of this printer is its precision in handling A4-sized PET films, which are ideal for a broad range of apparel sizes. This specificity ensures that designs are printed efficiently and with minimal waste, a crucial factor in both small-scale and bulk productions.

The printer’s ink delivery system is engineered to provide consistent, vibrant color output. It uses high-quality DTF inks that are formulated to be both bright and long-lasting. The inks adhere strongly to the films and transfer cleanly to fabrics, resulting in prints that retain their color even after multiple washes. This reliability in ink performance is crucial for businesses that aim to produce garments with prints that can endure regular wear and laundering.

Additionally, the Procolored A4 DTF printer is designed for user-friendly operation. It caters to both beginners and seasoned professionals, with settings that are straightforward to adjust and a learning curve that is manageable for newcomers to DTF printing. The printer’s build quality and durability also mean that it requires less frequent maintenance, ensuring more uptime and productivity.

What truly sets this printer apart is the support and community surrounding it. Procolored is known for its customer-focused approach, providing comprehensive support and resources. This includes detailed guides, technical support, and access to a community of users and experts. Such resources are invaluable, especially in an industry where technology and techniques evolve rapidly.

By integrating this printer into their workflow, businesses can not only elevate the quality of their prints but also enjoy a more efficient, reliable printing process. It embodies the confluence of innovation, quality, and user-friendliness, making it a stellar choice for anyone serious about producing top-tier DTF prints.

9. Committing to Continuous Learning and Innovation

The DTF printing landscape is dynamic, with continuous advancements shaping the industry. Staying informed about these changes is crucial. Engaging with DTF communities, participating in forums, and attending webinars or trade shows keeps you at the forefront of the industry. Companies like Procolored often share valuable insights and updates, which are instrumental in keeping your DTF printing processes cutting-edge.

Conclusion

By following these guidelines, from selecting the right equipment to embracing continuous learning, you can ensure that your DTF prints not only captivate but also endure. In an industry where quality and durability are paramount, adhering to these best practices will position your business at the pinnacle of success.

Disclaimer: This article contains sponsored marketing content. It is intended for promotional purposes and should not be considered as an endorsement or recommendation by our website. Readers are encouraged to conduct their own research and exercise their own judgment before making any decisions based on the information provided in this article.