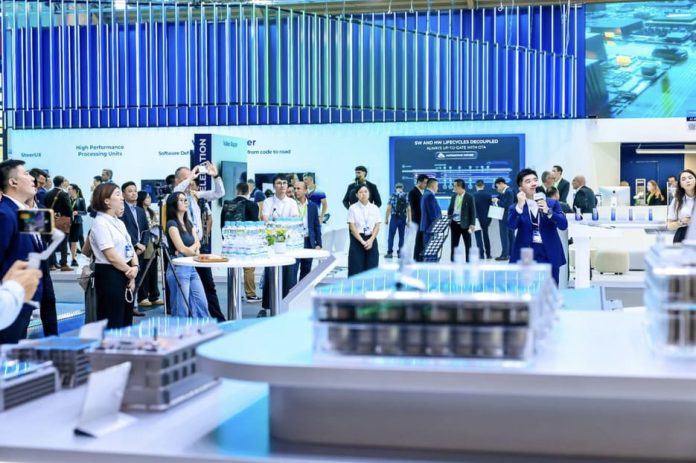

EVE Energy’s appearance at IAA Mobility 2025 captured industry attention. EVE utilized its OMNICELL large-cylindrical cell and system messaging to highlight globalization driven by Chinese innovation and enhanced cell-to-pack development agility. And according to Dr. Vincent Liang of EVE Energy Power Battery Research Institute, “For decades, cars were defined by one heart: the combustion engine. Today, that heart is the battery. But the industry still struggles with complex, rigid packs, and it’s time for a new solution.”

China’s EV Supply Chain Meets Global Platforms

China’s dominance in the EV ecosystem is undeniable. As the world’s largest EV battery producer supplying the vast majority of batteries for mining, refining, and cell manufacturing, Chinese firms have provided global EV programs with critical stability and scale. This foundation propels rapidly evolving exports, with a significant leap from a negligible to a substantial share in EU markets.

EVE Energy, riding this wave, has grown from a Chinese tier-1 battery supplier into a globally networked firm. It now operates regional headquarters across Asia, and has major facilities in Hungary and Malaysia, mirroring Europe’s localization expectations and underscoring its readiness for global OEM collaboration.

During IAA, EVE’s made clear that they’re responsibly embedding themselves into global supply architectures. In the current landscape, where trade barriers and geopolitical risks challenge global sourcing, EVE’s footprint, both inside and outside China, signals resilience and partnership fluency.

OMNICELL: A Platform-Ready Battery for a Multi-Market Era

EVE’s OMNICELL is about a unifying platform. Designed in a large cylindrical format that can be chemistry-tuned from LFP to NCM, without altering mechanical pack structures, it embodies modular versatility. With this, OEMs can deploy the same platform globally while customizing energy density, thermal behavior, and fast-charging characteristics by region or vehicle segment.

OMNICELL is engineered for CTP (cell-to-pack) integration, meaning the same cell family can feed directly into modular pack designs without requiring major requalification or tooling changes. That translates into faster system rollout, parallel thermo-BMS tuning, and streamlined safety validation across markets.

That matters. As vehicle cycles shorten and regions demand tailored range/charge specifications, a stable battery platform enables concurrent engineering.

Global Integration

EVE’s approach crystallizes a broader industry shift: leveraging Chinese manufacturing scale and innovation not as an isolated supply, but as a backbone for global program execution. By combining massive production capacity with on-ground presence in Europe and Asia, EVE mitigates geopolitical shock while offering OEMs unified technical platforms and deployment efficiency.

At IAA, with Omnicell, they are seeing a synchronizing element that bridges Chinese innovation and global program design. EVE Energy framed its role not as “China-based supplier,” but as “global enabler.” OMNICELL craftily translates EVE Energy’s strengths into assets valued by global OEMs: easier homologation, cross-regional reusability, and adaptable energy platforms.

The photos in the article are provided by the company(s) mentioned in the article and are used with permission.

Disclaimer: This article contains sponsored marketing content. It is intended for promotional purposes and should not be considered as an endorsement or recommendation by our website. Readers are encouraged to conduct their own research and exercise their own judgment before making any decisions based on the information provided in this article.