Extrusion is a manufacturing technique that makes objects with a constant cross section by pushing a material through a shaped die. This process is suitable for a variety of materials, including metals, plastics, ceramics, concrete, clay, and even food.

It is particularly suitable for producing complex shapes and for processing fragile materials, as these are subjected only to compressive and shear stresses, reducing the risk of breakage.

The process can be carried out in two modes: continuous extrusion, which generates products of indefinite length, and semi-continuous, used to make individual elements. Items made by this method are called “extrusions” and are distinguished by high surface quality and, in the case of metals, excellent structural strength.

Let’s find out, then, more about this technique and its benefits.

Extrusion lines

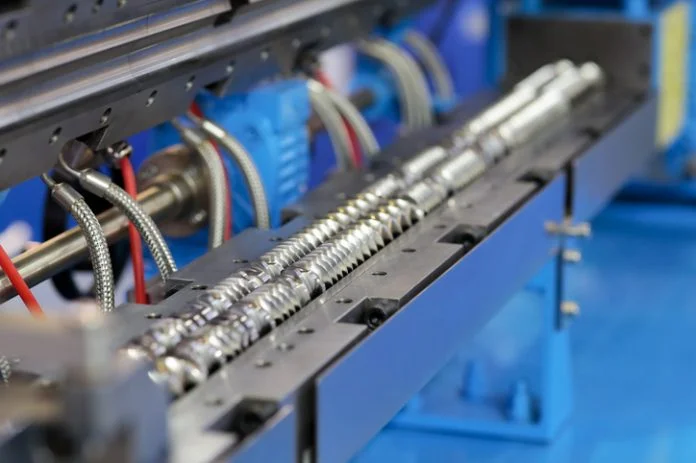

An extrusion line is an industrial system designed to transform plastic materials into continuous products such as sheets, plates or pipes. At the heart of this system is the extruder, a device capable of melting and mixing plastic material, then pushing it through a flat head or a shaped die to give it the required shape.

Depending on the ultimate application, the extrusion line can be combined with various auxiliary equipment for cooling, cutting, sizing, or winding the final product.

There are specific lines for plastic pipe extrusion, capable of processing a wide range of thermoplastic materials. These include PVC, in both soft and rigid versions, including transparent, filled with additives or combined with acrylic resins; CPVC (chlorinated polyvinyl chloride), which is particularly resistant to heat and chemicals; and polyolefins (PO) such as PE (polyethylene), PP (polypropylene), HDPE and LDPE, used for their versatility and strength.

The lines can also process composites such as WPC (Wood Plastic Composite), made on a PVC or polyolefin base, used for applications requiring high durability and wood-like aesthetic performance.

Different types of extrusion

There are different modes of extrusion. Hot extrusion is carried out by heating the material above its recrystallization temperature, thus preventing it from hardening and facilitating its passage through the die.

Cold extrusion, on the other hand, takes place at intermediate temperatures, which are higher than ambient but lower than the recrystallization temperature. This is a technique that balances ease of processing with final product properties.

Another method involves room-temperature extrusion, which offers several advantages such as no oxidation, greater strength due to cold treatment, more precise tolerances, and higher quality finishes.

Then there is friction extrusion, introduced in 1991 by the Welding Institute, which relies on the rotation of the raw material around the die, improving homogeneity in alloys. Finally, microextrusion allows the production of extremely small profiles, with cross sections of less than one millimeter, and this is the perfect solution for applications requiring high precision. Again, the metal is “pushed” through a die, even if it is small in size.

Extrusion’s benefits

Extrusion is a process which is chosen for multiple reasons. Among the major ones, it is possible to mention:

- Versatility: the extrusion process is extremely versatile and allows the production of a wide range of products with different shapes and sizes. It is best suited for the production of tubes, profiles, sheets and three-dimensional objects, even with complex geometries. This makes it particularly appropriate for machining plastics, where continuous, hollow, multichannel or customized sections can be obtained according to the final application;

- Wide range of materials that can be processed: as mentioned above, extrusion allows processing of numerous types of plastic materials. In addition, fillers, colorants, additives, or multiple resins can be added to achieve specific technical and aesthetic characteristics, thus improving the performance of the final product;

- High efficiency: extrusion enables high productivity with reduced costs. Production occurs quickly and uniformly, making the system ideal for large volumes and for integration into automated industrial lines;

- Final product quality: the extruded product has a good quality surface finish, which can be glossy, matte or textured. It also ensures uniformity and repeatability even over large batches, keeping dimensions and technical characteristics constant;

- Reduced costs: the extrusion process is cost-effective, especially for the production of long, continuous profiles. Optimal use of raw material allows significant reduction of waste, with the possibility of recycling nonconforming material;

- Extensive durability: extruded products offer optimal durability against wear, chemicals and weathering, ensuring long service life.

Therefore, extrusion represents a highly efficient, reliable and profitable technology for processing plastics. Due to its versatility, it enables the manufacture of products from the simplest to the most complex shapes, meeting the needs of numerous industries.

The possibility of employing a wide range of materials and customizing them with different additives and finishes makes the process extremely flexible. It also enables waste and cost reduction.

Disclaimer: This article contains sponsored marketing content. It is intended for promotional purposes and should not be considered as an endorsement or recommendation by our website. Readers are encouraged to conduct their own research and exercise their own judgment before making any decisions based on the information provided in this article.