When it comes to transporting goods safely, securing your cargo is not just a recommendation—it’s a necessity. Whether you’re a professional hauler, a construction worker, or someone moving household items, the right equipment can make all the difference in ensuring your load arrives intact and on time. Among the many tools available, ratchet straps stand out as a reliable, versatile, and effective solution for keeping cargo firmly in place. Lifting Equipment Store USA is a trusted name in the industry, known for providing high-quality ratchet straps designed to meet diverse cargo securing needs. This article will guide you through everything you need to know about ratchet straps, why the right choice matters, and how Lifting Equipment Store USA can help you secure your cargo with confidence.

Understanding Ratchet Straps

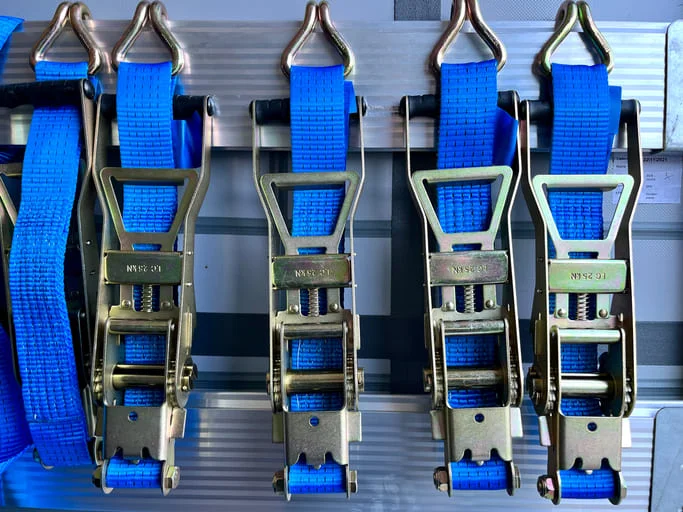

Ratchet straps, often known as tie-down straps, are specialized tools used to secure cargo during transportation. Unlike simple ropes or bungee cords, ratchet straps offer controlled tension and greater holding power, reducing the risk of cargo shifting or falling during transit. The essential components of a ratchet strap include the strap itself, typically made from strong synthetic fibers like polyester, and the ratchet mechanism, which allows users to tighten the strap incrementally.

The ratchet mechanism works by engaging a lever and gear system that tightens the strap to a desired tension and holds it firmly in place. This system provides a secure grip that is far superior to knots or hooks alone. The ends of the straps are equipped with hooks or other fittings designed to anchor the strap to a truck bed, trailer, or other secure points.

Tie-Down Straps are widely used across industries, including freight hauling, construction, and even recreational activities like securing motorcycles or boats. Their ability to safely restrain cargo, regardless of shape or size, makes them indispensable.

Why Choosing the Right Ratchet Strap Matters

Choosing the right ratchet strap is crucial for a variety of reasons, starting with safety. Improperly secured cargo can shift, fall, or even cause accidents on the road, endangering the driver, other motorists, and pedestrians. Beyond safety, the right strap protects your cargo from damage caused by movement or impact. Whether hauling delicate machinery or heavy equipment, a secure load reduces the risk of costly repairs or replacements.

Moreover, regulations regarding cargo security are strict, especially for commercial transport. Many jurisdictions require cargo to be restrained using equipment that meets specific safety standards. Using inadequate or substandard straps could result in fines or legal liabilities.

Investing in high-quality ratchet straps is also cost-effective in the long run. Durable straps reduce the need for frequent replacements and lower the chances of cargo loss or damage claims, ultimately saving money and effort.

Features to Look for in High-Quality Ratchet Straps

Not all ratchet straps are created equal, and understanding their features can help you select the best option for your needs. The first and foremost consideration is the strap’s strength and load capacity. Manufacturers typically provide a working load limit (WLL) and breaking strength. The WLL represents the maximum safe load the strap can handle, while the breaking strength indicates the force required to break the strap under ideal conditions. Choosing a strap with an appropriate WLL for your cargo is essential.

Material quality plays a significant role in the durability of ratchet straps. Polyester webbing is a common choice because it resists UV rays, abrasion, and moisture, ensuring longevity even when exposed to harsh outdoor conditions. The ratchet mechanism itself should be constructed from sturdy metals like steel with corrosion-resistant coatings to prevent rust and mechanical failure.

Finally, certifications and compliance with industry standards such as those set by the Department of Transportation (DOT) or Occupational Safety and Health Administration (OSHA) guarantee the strap’s reliability and safety.

How to Properly Use Ratchet Straps for Maximum Security

Using ratchet straps correctly is key to ensuring your cargo stays secure throughout the journey. Begin by inspecting your straps for signs of wear, fraying, or damage before every use. A compromised strap can fail under tension and jeopardize safety.

To secure cargo, position the strap over or around the load and anchor the hooks to solid attachment points on the vehicle or trailer. Feed the loose end of the strap through the ratchet spool and pull it tight by hand to remove slack. Then engage the ratchet lever repeatedly to tighten the strap further until the cargo is firmly immobilized. Avoid over-tightening, which can damage the cargo or the strap.

Always route the strap so that it avoids sharp edges or abrasive surfaces, or use edge protectors to prevent cutting. After tightening, lock the ratchet in place and secure the excess strap to prevent it from flapping during transport.

Conclusion

Securing your cargo properly is essential to safe, efficient transportation. Ratchet straps offer a powerful, reliable way to keep your load firmly in place, protecting both your cargo and those on the road. By understanding what makes a quality ratchet strap and selecting top-rated products from Lifting Equipment Store USA, you can transport your goods with confidence and peace of mind. Don’t leave your cargo’s safety to chance—choose trusted ratchet straps designed for performance and durability. Secure your cargo today and experience the assurance that comes with quality equipment.

Disclaimer: This article contains sponsored marketing content. It is intended for promotional purposes and should not be considered as an endorsement or recommendation by our website. Readers are encouraged to conduct their own research and exercise their own judgment before making any decisions based on the information provided in this article.