Whether you’re curious about the artistry behind luxury pieces or considering purchasing custom jewelry, understanding the jewelry manufacturing process reveals the skill, precision, and technology that transform raw materials into wearable art.

Jewelry manufacturing blends art, engineering, and meticulous handwork. Understanding the process helps you spot quality, set realistic expectations for custom orders, and appreciate why fine jewelry costs what it does.

This guide walks through every major stage: design, modeling, casting, fabrication, stone setting, finishing, and quality control. It also highlights where time, skill, and technology make the biggest difference.

Why Jewelry Manufacturing Matters

Most “how is jewelry made” explanations stop at a simple list of steps. In reality, every decision from metal choice to setting style affects durability, comfort, and long-term value.

Knowing the process helps you:

- Understand why two similar-looking pieces can have very different prices.

- Ask better questions when ordering custom jewelry.

- Recognize shortcuts that compromise quality.

Step 1: The Jewelry Design Phase

Design is where jewelry starts, and weak design cannot be fixed later in the process. Good designers balance aesthetics, structure, and wearability before any metal is melted.

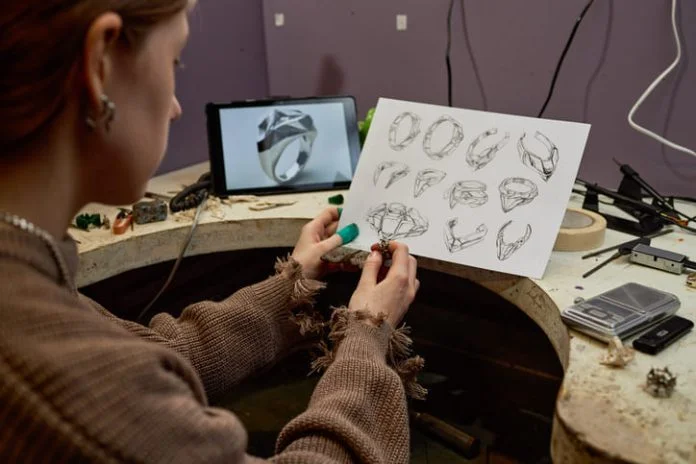

From Idea to Sketch

Most pieces begin with a concept: an engagement ring idea, a custom pendant, or a rework of heirloom stones. Designers translate that concept into:

- Hand-drawn sketches from multiple angles.

- Quick variations to test stone shapes, band widths, and proportions.

- Notes on metal type, stone size, and setting style.

Even at this stage, practical factors matter: how high a stone sits, whether a ring will catch on clothing, and how heavy a pendant will feel on the neck.

CAD and 3D Jewelry Design

Once the idea is clear, Computer-Aided Design (CAD) software turns it into a precise 3D model. This step allows:

- Accurate measurements for stones and metal thickness.

- Simulation of how light will interact with facets and metal surfaces.

- Early detection of structural weaknesses, such as overly thin prongs.

For more complex designs (for example, pavé bands or fully iced-out pendants), CAD is essential to ensure every stone seat is accurate before any physical model is produced.

Step 2: Master Model and Wax Pattern Creation

The master model becomes the blueprint for casting. Precision here determines how much rework is needed later.

3D Printed and Hand-Carved Wax Models

There are two main ways to create a jewelry model:

3D printed wax or resin models

CAD files are fed into high-resolution printers that produce a detailed wax or resin version of the design. This is ideal for intricate patterns, micro-pavé surfaces, and geometric shapes.

Hand-carved wax models

Experienced wax carvers use files, blades, and warm wax to sculpt the model by hand. This approach suits organic shapes and one-of-a-kind artisanal designs.

In both cases, the model must account for metal shrinkage during casting and polishing. A ring, for example, is modeled slightly larger than the final size.

Preparing for Reproduction: Rubber or Silicone Molds

If the design is to be made more than once, a mold is created from the master model:

- The wax or metal master is embedded in rubber or silicone.

- Heat and pressure vulcanize the mold around it.

- After cooling, the mold is cut open, and a cavity in the exact shape of the jewelry remains.

This mold can then be used to inject wax repeatedly, producing consistent wax patterns for casting.

Step 3: The Lost Wax Casting Process

Lost wax casting is the backbone of modern jewelry manufacturing. It transforms fragile wax patterns into solid metal.

Building the Wax Tree

Individual wax models are:

- Attached to a central wax stem (called a “sprue” or “tree”).

- Arranged so that metal can flow evenly to every piece.

- Checked for orientation to minimize defects and make cleanup easier.

One tree can hold multiple rings, pendants, or small components, depending on size and metal weight.

Investing and Burnout

The wax tree is then:

- Placed inside a metal cylinder (flask).

- Filled with liquid investment (a heat-resistant plaster slurry).

- Degassed to remove bubbles that could cause surface imperfections.

Once the investment hardens, the flask goes into a kiln. The wax melts and burns out, leaving a precise negative cavity of every piece inside the hardened investment. This is the “lost wax” stage.

Pouring the Molten Metal

Next, the chosen metal is prepared:

- Metal grains or ingots (gold, silver, platinum, or alternative alloys) are cleaned and melted.

- Temperature is controlled to ensure good flow and minimize porosity.

The molten metal is forced into the flask using:

- Vacuum casting

- Centrifugal force

- Gravity casting in some setups

After cooling, the investment is broken away, revealing a metal tree with each piece in place of the original wax.

Step 4: Metal Cleanup and Fabrication

Freshly cast jewelry is rough. It must be cut, cleaned, and often partially rebuilt before it looks like a finished piece.

Cutting and Cleaning the Casting

The jeweler:

- Cuts individual pieces off the metal tree.

- Grinds away the sprue marks where metal entered the piece.

- Removes surface residue and investment remnants.

This is followed by careful filing to:

- Smooth rough edges.

- Refine curves and angles.

- Prepare surfaces for polishing and stone setting.

Hand Fabrication and Structural Enhancements

Not all parts are cast. Many durable, high-end pieces combine casting with fabrication:

- Shanks, galleries, and settings may be built from sheet and wire.

- Soldering or laser welding joins multiple components.

- Extra reinforcement is added to stress points (for example, under stone seats, at band shoulders).

Fabrication is slower but allows the jeweler to strengthen areas that would be too thin or fragile if cast alone. This is a key difference between fast, mass-market jewelry and more robust, heirloom-quality pieces.

Step 5: Stone Selection and Setting

Stone setting is one of the most skilled parts of how jewelry is made. Poor setting leads to lost stones and uncomfortable wear.

Choosing Diamonds, Gemstones, and Moissanite

Before setting begins, stones are matched to the design:

- Diamonds and colored gemstones are graded for cut, clarity, color, and size.

- Lab-grown stones and moissanite are often selected for budget-friendly or high-sparkle pieces.

- Side stones are matched for consistency so the piece looks balanced.

Different designs call for different stone types. For example, moissanite is popular in modern hip-hop and urban jewelry because of its intense fire and brightness, especially in highly iced-out chains, pendants, and rings. If you’re interested in exploring fully iced jewelry styles, you can buy iced-out chains that showcase this brilliant aesthetic with superior craftsmanship.

Common Stone Setting Techniques

Setting styles affect both the final look and long-term security of the stones. Common methods include:

- Prong setting – Small metal claws hold the stone. This maximizes light but requires strong prongs.

- Bezel setting – A rim of metal surrounds the stone’s edge for excellent protection.

- Channel setting – Stones sit between two metal walls, frequently used in bands.

- Pavé and micro-pavé – Multiple small stones set closely with shared prongs for a continuous sparkle effect.

- Invisible setting – Stones slide into a grid with no visible metal between them; highly precise but difficult to repair.

Each stone is seated under magnification, aligned for symmetry, and secured with carefully tightened metal. If this stage is rushed, stones will loosen over time. For those seeking custom jewelry designs with specialized stone settings, working with experienced jewelers ensures each stone remains secure and properly displayed.

Step 6: Polishing, Plating, and Final Finishes

At this point, the piece looks complete but still lacks its final sheen. Finishing transforms clean metal into something that truly looks “fine.”

Multi-Stage Polishing

Polishing usually happens in several passes:

- Coarse compounds remove fine scratches from filing and sanding.

- Medium-grade compounds even out surfaces.

- Final bright polish brings out mirror shine.

Delicate areas around stones and engravings are often hand-polished with small brushes or wheels to avoid rounding edges or damaging settings.

Surface Treatments and Plating

Depending on the design and metal:

- White gold is often rhodium-plated to enhance whiteness and shine.

- Some pieces receive matte, brushed, hammered, or sandblasted textures for visual interest.

- Anti-tarnish treatments may be applied to silver.

These finishes influence how the piece looks in real-world lighting and how often it needs maintenance. Just as quality finishing matters for jewelry, maintaining your personal appearance with proper grooming enhances your overall style. Consider exploring premium men’s grooming products to complement your refined jewelry collection.

Step 7: Quality Control and Certification

Quality control is not one moment; it is a set of checks at several points before a piece leaves the workshop.

Structural and Visual Checks

A thorough inspection includes:

- Checking every stone for movement or gaps.

- Examining prongs, bezels, and solder seams for cracks or porosity.

- Inspecting surfaces for scratches, pits, and uneven polishing.

- Confirming ring sizes, chain lengths, and clasp function.

Any issue at this stage is corrected before the piece is packaged or presented to a client.

Hallmarking and Gemstone Certification

To verify authenticity and reassure buyers:

- Metal purity is stamped according to local regulations (for example, 14K, 18K, 925).

- High-value stones may be accompanied by third-party grading reports.

- Workmanship guarantees or warranties may be provided.

Understanding these marks and documents helps buyers distinguish serious jewelry makers from low-cost, unverified sellers.

How Long Does It Take to Make Jewelry?

Timelines vary based on complexity, materials, and whether a piece is custom or part of a repeated design.

Typical Manufacturing Timeline

A realistic schedule for a custom piece might look like this:

- Design and CAD: 3–7 days (longer if many revisions)

- Model and mold (if needed): 2–5 days

- Casting and initial cleanup: 1–3 days

- Fabrication and structural work: 3–10 days

- Stone setting: 2–7 days

- Final finishing and quality control: 1–3 days

In total, a single piece can take anywhere from one to four weeks of active work, especially for complex designs with many stones or intricate metalwork.

Why Some Jewelry Costs More Than It Looks

Several hidden factors increase the cost even if the piece looks simple:

- Time spent on design and adjustments.

- Multiple remake cycles if the first casting is not perfect.

- Skilled labor for hand setting and fabrication.

- Quality control and after-sales support.

When you understand how jewelry is made, price differences between pieces start to make sense. For jewelry businesses looking to enhance their online visibility and reach customers searching for custom pieces, implementing effective SEO strategies can significantly improve your website’s search rankings and attract qualified buyers.

How to Judge Jewelry Quality as a Buyer

Knowing the manufacturing stages is useful, but buyers also need practical ways to evaluate finished pieces.

Questions to Ask Before You Buy

When viewing or ordering jewelry, consider asking:

- Was this piece cast, fabricated, or a mix of both?

- How are the stones set, and what warranties cover stone loss?

- What metal alloy is used, and is it hallmarked?

- Can the maker explain their polishing and finishing standards?

Clear, confident answers are a good sign you are dealing with a serious maker, not a low-effort reseller.

Visual and Practical Checks

A quick inspection can reveal a lot:

- Are prongs even and secure, with no sharp hooks?

- Are stones centered, matched, and aligned?

- Does the piece feel solid, not overly light for its size?

- Are edges comfortable where the jewelry contacts skin?

Combining this visual check with an understanding of the process gives you a much clearer sense of what you are buying. If you’re sharing your jewelry collection on social media, building genuine engagement through social media growth services can help you connect with fellow jewelry enthusiasts and potential customers who appreciate quality craftsmanship.

Understanding the Value Behind Every Piece

When someone asks, How is jewelry made?” the real answer is more than six neat steps. Behind every polished piece is a full system: thoughtful design, precise modeling, carefully controlled casting, meticulous fabrication, expert stone setting, layered polishing, and rigorous quality control.

Understanding that journey turns jewelry from a simple accessory into something you can evaluate, respect, and enjoy with full appreciation for the work that made it possible. Whether you’re purchasing a custom piece, starting your own jewelry business, or simply admiring fine craftsmanship, knowing what goes into creating quality jewelry empowers you to make informed decisions and recognize true artistry when you see it.

The next time you hold a beautifully crafted ring, pendant, or bracelet, you’ll know the intricate process that transformed raw materials into a lasting treasure from the first sketch to the final quality inspection.