By Richard Hatfield

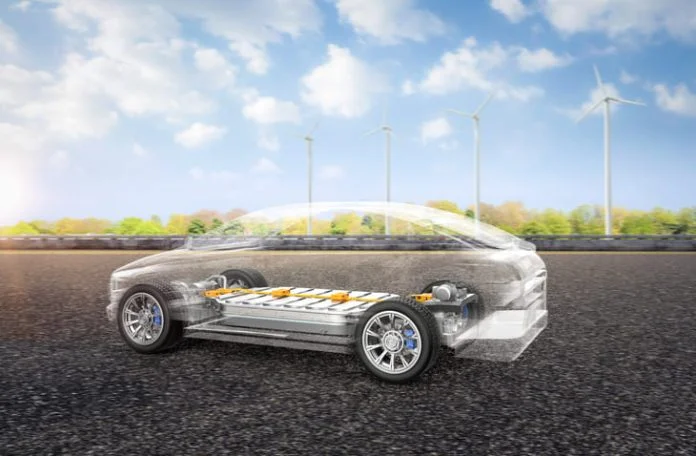

The article argues that 800V battery architecture—not breakthrough cell chemistry—is the decisive lever for scalable, profitable EVs. By reducing current, heat, and material costs, 800V systems improve capital efficiency, fleet uptime, and residual value while future-proofing vehicles for ultra-fast charging infrastructure. Architecture, not chemistry, drives commercial success in modern markets.

As the global automotive industry moves toward mass-market electrification, a dangerous misconception persists among decision-makers: that the path to faster charging lies solely in the hands of materials scientists.

While billions are funneled into “wonder” cell chemistries like solid-state and silicon anodes, many OEMs are ignoring a systemic bottleneck already sitting on their assembly lines. Our experience at Lightning Motors—pioneering the first production 800V motorcycle—has demonstrated that battery architecture, not chemistry, is the primary determinant of commercial success in the high-performance EV market.

1. Capital Efficiency: Copper vs.Voltage

In a 400V system, the only way to increase charging speed is to increase amperage (current). This creates a domino effect of rising costs:

- Heavier Bill of Materials (BOM): High current requires thicker, more expensive copper wiring and connectors.

- Thermal Overhead: Increased current generates heat exponentially (I^2R), requiring larger, more complex, and more expensive liquid-cooling systems.

By pivoting to an 800V architecture, we achieve a “Power-to-Weight” breakthrough. We can deliver the same power with half the current, allowing for thinner wiring and downsized cooling hardware. For the OEM, this isn’t just an engineering win; it is a weight and cost-reduction strategy that directly improves margins.

2. Operational ROI: The “Downtime” Tax

For commercial fleets and high-utilization vehicles, time is literally money. A vehicle that is thermally limited during charging is an underutilized asset.

- Thermal Throttling: In 400V packs, the Battery Management System (BMS) is frequently forced to “derate” charging speeds to protect the hardware from current-induced heat.

- Throughput: An 800V system maintains peak charging rates for longer durations. This reduces the “dwell time” at chargers, increasing daily vehicle uptime and operational throughput.

3. Future-Proofing and Residual Value

The EV market is currently split into “Generation 1” (400V) and “Generation 2” (800V+). As 350kW+ ultra-fast charging infrastructure becomes the global standard, 400V vehicles are at risk of rapid depreciation.

From a strategic perspective, investing in high-voltage architecture is a hedge against obsolescence. Vehicles built on 800V platforms will retain higher resale value because they remain compatible with the next decade’s high-speed charging networks.

The Strategic Takeaway

Ultimately, charging speed is influenced by a complex ecosystem of factors; however, battery pack architecture is the foundational element that dictates whether a vehicle can safely and consistently translate its potential into real-world performance and profit.

For the modern automotive executive, the choice is clear: you can wait for a breakthrough in chemistry that may be years away, or you can optimize your architecture today to unlock the power you already have.

Richard Hatfield

Richard Hatfield