By Cory Searcy

A growing number of companies are working to develop sustainable supply chains. A key challenge is to align their supply chain performance with the economic, environmental, and social thresholds that dictate whether it is sustainable or not. This article discusses what supply chain sustainability really means, why it is difficult to achieve, and what companies can do to advance their progress.

Nearly every day, more companies publicly share their sustainability commitments and progress. As just one example, nearly 10,000 companies around the world are now signatories to the United Nations Global Compact. These companies have explicitly recognised their responsibilities in the areas of human rights, labour, environment, and anti-corruption.1

Many companies now acknowledge that their responsibilities extend into their supply chains. In fact, supply chains often contain a company’s most significant impacts. In 2010, PUMA found that 94% of its total environmental impact was generated within its supply chain.2 This past year alone, Walmart, Mars, and Hewlett Packard Enterprise (HPE) were just a few of the companies to announce dramatic expansions of their sustainable supply chain initiatives.

The growing investments in sustainable supply chains are encouraging. However, extending sustainability into supply chains comes with many challenges. Companies must set priorities, accommodate differing local conditions, and align the efforts of a multitude of partners. But first, they must figure out what sustainability means for their supply chain. Only then can they determine if they are doing enough of what truly matters.

[ms-protect-content id=”9932″]

What is a sustainable supply chain?

There are many definitions of supply chains, but they typically emphasise the need to coordinate flows of material, services, and information between organisations in order to deliver value to customers. Definitions of sustainable supply chains usually add the requirement to address the “triple bottom line” of economic, environmental, and social performance.3 Definitions based on the triple bottom line, however, are insufficient because they do not plainly distinguish sustainable supply chains from unsustainable ones.

To do this, explicit references to the “limits and demands placed on economic, environmental, or social resources, at the sectoral, local, regional, or global level”4 are required. The limits and demands on resources are the basis for identifying sustainability thresholds. Thresholds can represent upper limits, such as for atmospheric greenhouse gases (GHGs), or lower limits, such as for living wages.5

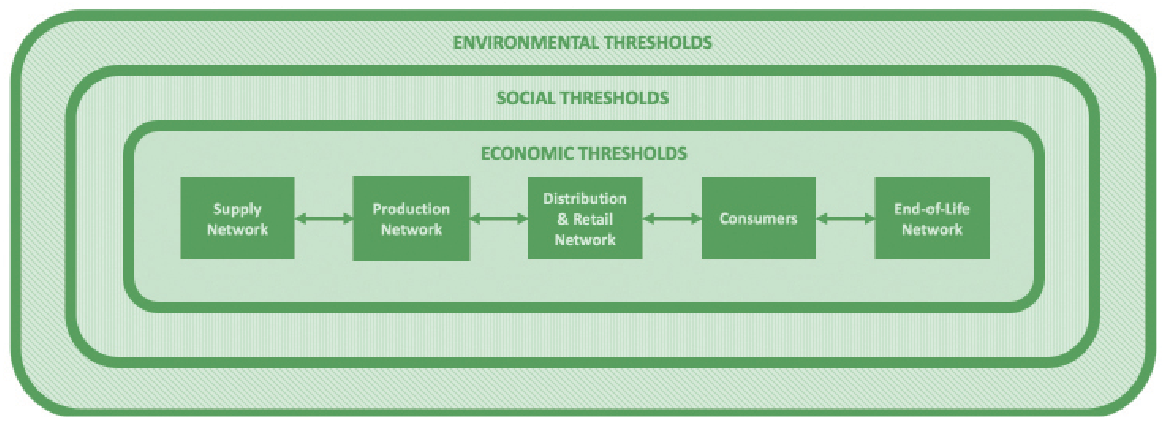

Staying within thresholds is fundamentally what sustainability is about. A sustainable supply chain operates “within the thresholds imposed by nature and society”.6 To remain viable, a supply chain must also operate within economic thresholds imposed by the company’s stakeholders. This definition is based on the embedded view, which recognises that all supply chain activities take place in the context of broader society, which is itself nested within the natural environment.7

Figure 1 depicts the embedded view of sustainable supply chains. In the middle of the figure is a generic supply chain. The key players include suppliers, manufacturers, distributors, retailers, and consumers. Product end-of-life considerations, such as reuse, recycling, and disposal, are also considered. To reflect the potential complexity of the relationships in the chain, the focus is on networks, rather than dyadic relationships. Moreover, the double-headed arrows indicate that sustainable supply chains must consider forward and reverse flows between players.

Figure 1: The Embedded View of Sustainable Supply Chains

The focal company can be located anywhere along the supply chain. This company is responsible for determining the key sustainability thresholds for its supply chain. Economic thresholds could, for example, focus on profitability or competitive practices. Environmental thresholds could focus on water consumption or GHG emissions. Social thresholds could focus on workplace safety or living wages.5 Different supply chains could have different relevant thresholds.

To be clear, a supply chain is only sustainable if it operates within all of its defined thresholds. Recognising responsibilities, making investments, and improving performance over time are all commendable and these types of proactive efforts must be encouraged. But, supply chain sustainability is not about best efforts; it is about staying within thresholds. This is not easy.

Challenges in Building Sustainable Supply Chains

There are many challenges in building sustainable supply chains. The emphasis here is on measuring sustainability performance. Of course, there are many actions companies must take beyond measurement, such as re-designing their products or implementing supplier codes of conduct. Performance measurement is the foundation, however, for identifying priorities and determining whether or not the supply chain is operating within economic, environmental, and social thresholds.

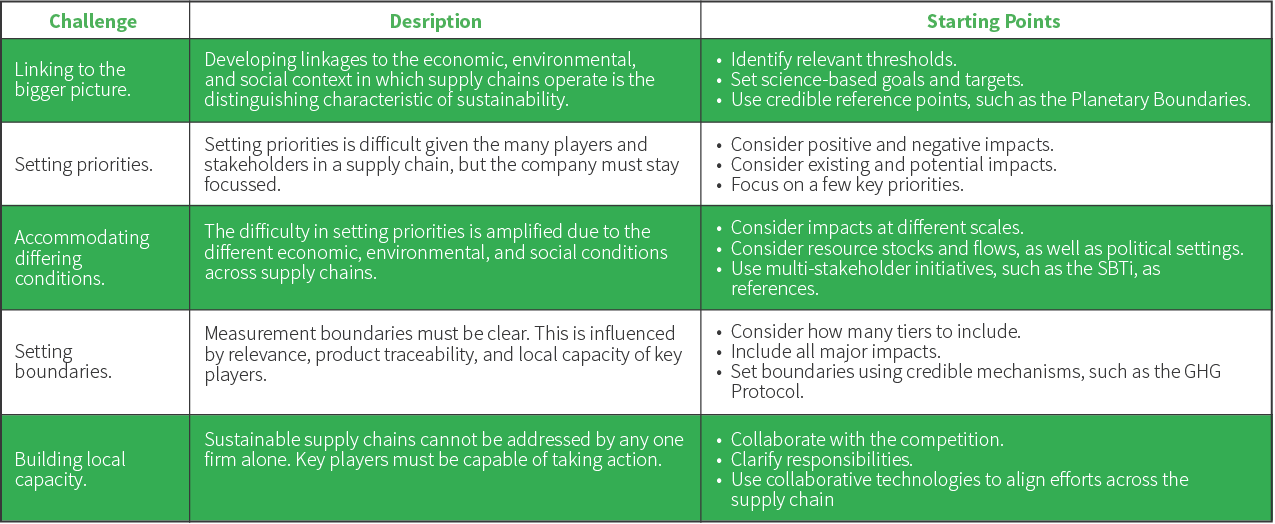

Table 1 summarises five representative challenges in measuring supply chain sustainability, as well as how companies can get started in addressing them. These challenges must be overcome to develop credible sustainability metrics.

Table 1: Challenges in Measuring Sustainability in Supply Chains

Linking to the bigger picture. The first key challenge is determining how the supply chain influences, and is influenced by, the wider world. This requires identifying the relevant economic, environmental, and social thresholds and then finding a way to translate them to the supply chain level.

Examples of potential thresholds abound. The Planetary Boundaries8 framework identifies nine key thresholds based on environmental science, including climate change and global freshwater use. The Doughnut9 framework builds on The Planetary Boundaries and adds 12 thresholds based on social science and ethics, such as for health and social equity. The 17 goals and 169 targets provided by the United Nations Sustainable Development Goals (SDGs)10 serve as another potential reference point.

Few thresholds, however, have been specifically developed for the supply chain level. Science- and ethics-based goals, grounded in “scientific knowledge” and “norms of fairness, justice, integrity, and respect”,11 respectively, can help bridge this gap. Setting these goals can be difficult given evolving scientific understanding and social norms, but the key is that they are non-arbitrary, linked to meaningful thresholds, and are updated as needed.

Setting priorities. No supply chain can address all conceivable economic, environmental, and social thresholds. The company must ensure that it considers its key impacts, while staying focussed on what matters most. This must be considered in light of the players and other stakeholders in the supply chain.

The CDP, formerly the Carbon Disclosure Project, runs a supply chain programme focussed on the three key issues of climate change, water, and forest-risk management.12 Addressing any one of these issues in a complex supply chain is difficult given the need to collect timely, reliable, and valid data. This is further complicated by the need to develop credible science-based targets, as the CDP is doing for climate change,13 as well as the need to consider existing and potential, positive and negative, and short- and long-term impacts. Given these challenges, companies must stay focussed on essential priorities.

Accommodating differing conditions. Supply chains often cross multiple political and regulatory boundaries. The economic, environmental, and social conditions across the chain can also vary widely. For example, impacts from climate change have global implications. Water usage, on the other hand, is mainly a regional issue. A level of water use may be acceptable in one part of the chain, but not another.

There are a number of multi-stakeholder initiatives that provide guidance on how to address thresholds at different scales. For example, the rapidly growing Science Based Targets Initiative (SBTi) provides guidance and support to companies on setting GHG targets in line with climate science.14 The SBTi requires signatories to consider their value chain emissions. The CEO Water Mandate is developing context-based water targets,15 taking into account hydro-ecological conditions at the water basin level. Other examples will likely emerge.

Setting boundaries. The boundaries for measurement must be clear, but this can be difficult in large supply chains. No key players should be excluded to ensure all key impacts are captured. A fundamental decision is determining how many tiers of suppliers to consider, particularly given that risks often exist deep in the chain.16 Product traceability will be a factor in determining the number of tiers to consider.

Guidelines on setting boundaries are available for some issues, such as measuring GHG emissions. The GHG Protocol, for example, provides guidelines to quantify GHG emissions. Its main reporting standard contains a supplement on determining emissions throughout a company’s value chain.17 Other support is available, including an online calculator for value chain emissions. In any case, companies must be clear on the boundaries used to determine and develop their impacts and metrics.

Building local capacity. Sustainable supply chains depend on the collaboration of many players. To develop metrics, for example, all key players must have a common understanding of terminology, definitions, and responsibilities, as well as possess credible data collection and analysis systems. Reporting systems must also be compatible, which requires strong relationships and collaborative technological platforms.

For many issues, building local capacity may be beyond the power of any one company alone. Companies should consider collaborating with others, including their competition, on issues that are not competitive differentiators. For example, a number of industry-led initiatives have focussed on improving working conditions deep in the supply chain. The Electronic Industry Citizenship Coalition’s Code of Conduct18 is a prime example.

Best Practice Examples

Many companies have begun the long process of addressing these challenges. While none have perfectly addressed all of their supply chain sustainability challenges, many have taken commendable action. Consider three recent examples, each with a major focus on GHG emissions.

In September 2017, Mars announced a $1 billion USD investment in its Sustainable in a Generation Plan, which includes a focus on both the company’s direct operations and its value chain.19 One key commitment is to reduce the company’s GHG emissions in line with climate science. Mars has worked with the World Resources Institute to develop science-based targets and metrics for GHGs, as well as for land and water.20 Mars has committed to reducing GHG emissions across its value chain by 27% by 2025 and 67% by 2050.19

Earlier in 2017, in May, HPE announced that it would establish science-based goals to reduce GHG emissions in its supply chain.21 The goal is to reduce HPE’s supply chain emissions from manufacturing by 15% by 2025. Notably, HPE also committed to provide its suppliers with support to help build their local capabilities. The company expects that 80% of its manufacturing suppliers will set their own science-based targets by 2025.

Walmart has long focussed on the sustainability of its supply chain. In April 2017, it announced Project Gigaton, which aims to reduce the company’s supply chain GHG emissions by 1 gigaton by 2030.22 Along with Mars and HPE, Walmart is a member of the SBTi and has committed to setting its GHG emissions targets in line with climate science. Walmart has also established a number of other sustainability goals, such as reducing its waste to zero throughout its supply chain by 2025.

All three of these companies, and many others, have begun taking action based on what scientific evidence indicates is required. Importantly, however, companies do not have to address sustainability in their supply chains alone. Multi-stakeholder initiatives, such as the SBTi and the CEO Water Mandate, show how they can work with other companies, civil society, and other stakeholders to develop credible approaches to challenging scientific and ethical problems.

Despite the many ongoing efforts, however, there is much more to do. The CDP recently found that only 22% of the companies reporting to its supply chain programme are actively working with their suppliers to reduce carbon emissions.12 A study of 40,000 corporate responsibility reports found that just 5% referred to ecological limits.23 Another study of over 2,500 metrics used to measure performance in supply chains found that none adequately addressed the broader sustainability context.24

Institutionalising sustainability in supply chains requires engaging many more companies. Whether the focus is on GHG emissions or other economic, environmental, and social issues, companies must link their efforts to what nature and society can support.

Conclusion

Sustainability requires that supply chains operate within economic, environmental, and social thresholds. However, supply chain sustainability is not directly observable. There is room for reasonable debate on what impacts should receive priority, how performance should be linked to thresholds, and, ultimately, what should be done. But, difficult as these questions are, none are reasons to delay action.

No sustainable supply chain initiative is likely to be perfect, much less on the first try. The focus will also inevitably change over time. Thresholds, for example, will need to be updated as science, societal expectations, and the supply chain itself evolve. Metrics and action plans are also finite.

Companies will need to stay current on the latest research, look to others for inspiration, and collaborate widely to solve difficult problems. Most importantly, though, they need to get started with linking their supply chains to the wider world.

[/ms-protect-content]

About the Author

Cory Searcy is a Professor of Industrial Engineering and Environmental Applied Science & Management at Ryerson University. He currently serves as the Associate Dean, Programs in Ryerson’s Yeates School of Graduate Studies. He is also a section editor for corporate sustainability at the Journal of Business Ethics.

Cory Searcy is a Professor of Industrial Engineering and Environmental Applied Science & Management at Ryerson University. He currently serves as the Associate Dean, Programs in Ryerson’s Yeates School of Graduate Studies. He is also a section editor for corporate sustainability at the Journal of Business Ethics.

References

1. United Nations Global Compact (2017). Online: https://www.unglobalcompact.org/

2. PUMA (2011). PUMA’s environmental profit and loss account for the year ended 31 December 2010. Online: http://about.puma.com/damfiles/default/sustainability/environment/e-p-l/EPL080212final-3cdfc1bdca0821c6ec1cf4b89935bb5f.pdf

3. Ahi, P. & Searcy, C. (2013). A comparative literature analysis of definitions of green and sustainable supply chain management. Journal of Cleaner Production 52:329-341

4. Global Reporting Initiative (2016). Online: https://www.globalreporting.org/standards

5. Thomas, M. & McElroy, M. (2016). The MultiCapital Scorecard: Rethinking organizational performance. White River Junction, VT: Chelsea Green Publishing

6. Searcy, C. (2016). What makes a supply chain sustainable? MIT Sloan Management Review, Online: http://sloanreview.mit.edu/article/what-makes-a-supply-chain-sustainable/

7. Montabon, F., Pagell, M. & Wu, Z. (2016). Making sustainability sustainable. Journal of Supply Chain Management 52(2):11-27

8. Steffen, W. et al. (2015). Planetary boundaries: Guiding human development on a changing planet. Science 347(6223):736

9. Raworth, K. (2017). Doughnut economics: Seven ways to think like a 21st century economist. White River Junction, VT: Chelsea Green Publishing

10. United Nations (2015). Online: http://www.un.org/sustainabledevelopment/sustainable-development-goals/

11. McElroy, M. (2015). Science- vs. context-based metrics. Sustainable Brands, Online: http://www.sustainablebrands.com/news_and_views/new_metrics/mark_mcelroy/science-_vs_context-based_metrics_%E2%80%93_what%E2%80%99s_difference

12. CDP (2017). Missing link: Harnessing the power of purchasing for a sustainable future. Online: https://b8f65cb373b1b7b15feb-c70d8ead6ced550b4d987d7c03fcdd1d.ssl.cf3.rackcdn.com/cms/reports/documents/000/001/500/original/CDP-Supply-chain-report-2017.pdf?1490272235

13. CDP (2016). Technical note on science-based targets: CDP climate change 2016. Online: https://www.cdp.net/Documents/Guidance/2016/CDP-technical-note-science-based-targets.pdf

14. Science Based Targets Initiative (2017). Online: http://sciencebasedtargets.org/

15. CEO Water Mandate (2017). Exploring the case for corporate context-based water targets. Online: https://www.ceowatermandate.org/files/context-based-targets.pdf

16. Sheffi, Y. (2015). The tears in the deep tiers. The European Business Review November-December 2015, 57-62

17. GHG Protocol (2011). Corporate value chain (Scope 3) accounting and reporting standard. Online: http://www.ghgprotocol.org/sites/default/files/ghgp/standards/Corporate-Value-Chain-Accounting-Reporing-Standard_041613_2.pdf

18. Electronic Industry Citizenship Coalition (2014). Online: http://www.responsiblebusiness.org/media/docs/EICCCodeofConduct5_English.pdf

19. Mars (2017). Online: http://www.mars.com/global/sustainable-in-a-generation

20. WRI & Mars (2016). From doing better to doing enough: Anchoring corporate sustainability targets in science. Online: https://www.wri.org/sites/default/files/From_Doing_Better_to_Doing_Enough_Anchoring_Corporate_Sustainability_Targets_in_Science.pdf

21. HPE (2017). Online: https://news.hpe.com/hpe-launches-worlds-first-supply-chain-program-based-on-climate-science/

22. Walmart (2017). Online: https://news.walmart.com/2017/04/19/walmart-launches-project-gigaton-to-reduce-emissions-in-companys-supply-chain

23. Bjorn, A., Bey, N., Georg, S., Ropke, I., & Hauschild, MZ. (2017). Is Earth recognized as a finite system in corporate sustainability reporting? Journal of Cleaner Production 163:106-11

24. Ahi, P. & Searcy, C. (2015). An analysis of metrics used to measure performance in green and sustainable supply chains. Journal of Cleaner Production 86:360-377